Two weeks ago, I attended the National Investment Center for Seniors Housing & Care (NIC) in Washington, D.C. As always, it was good to see old friends and clients, and interesting to get a read on the industry. There were really no surprises, but it’s good to get intensive confirmation of what’s going on.

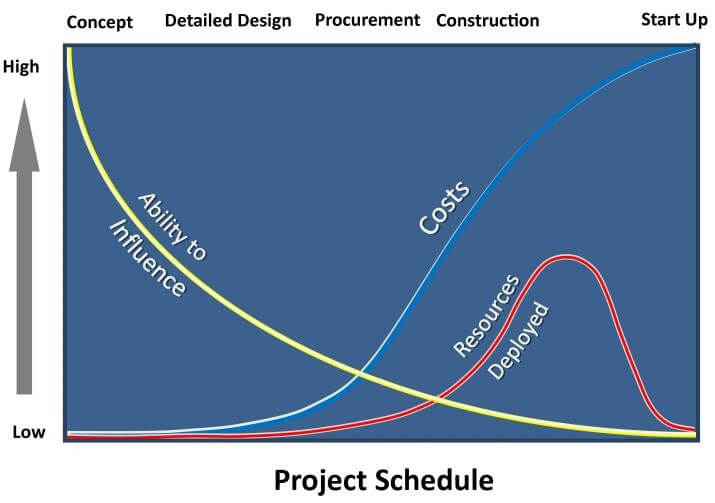

Senior living development is really a somewhat bifurcated proposition at this point. Though we are still building and have recently started a number of assisted living/memory care (AL/MC) projects, most of the developers are not bullish on this sector right now. Operating costs are up dramatically, interest rates and construction costs continue to rise, occupancies have not fully recovered, and rents have not yet risen to cover the increased expenses. There are some AL/MC developers that think that they just need to forge through, that it’s just a bump in the road and all will be good,...

Read More >