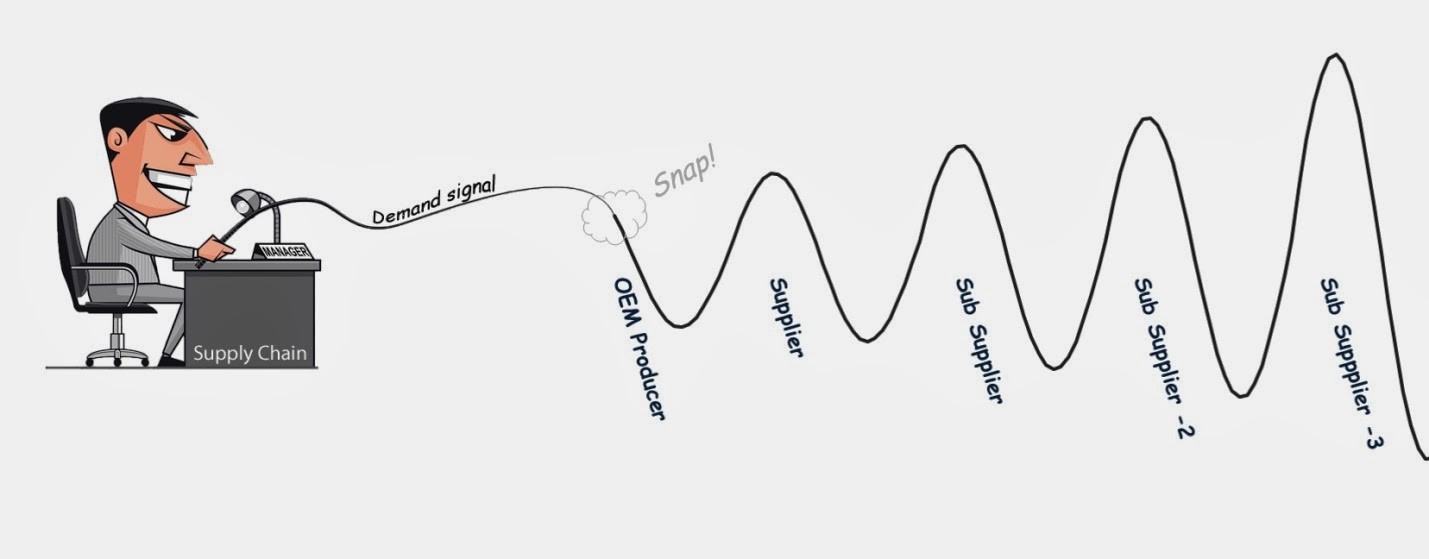

Remember when the pandemic hit, and everybody collected toilet paper? It’s happening today with subcontractors and vendors throughout the trades (not TP; material like rigid insulation, ductile iron pipe, copper pipe, drywall, lumber, metal studs, coiled steel, etc., etc.). Material price surges, a continuing supply chain roller coaster, and the omicron variant have us all guessing how long to receive and how much material will cost when it is finally installed on the job site. An extended construction duration and price increase pass through are deal breakers for us at The Douglas Company, so we are tested to come up with alternate methods to deal with the aforementioned challenges.

Our advanced procurement of construction materials and equipment soon after a contract is executed and well before the equipment or material is needed, is a sensible practice which assures that specified materials and equipment are available for installation or use in accordance...

Read More >